Ecology

|

The use of ecodye requires significantly less resources in terms of water, time and energy consumption while at the same time reducing CO2 emissions and protecting the environment. Textilcolor and Schoeller Technologies emphasize innovation in terms of performance and sustainability. ecodye only contains bluesign® approved components. Properly applied, it allows production with a minimum impact on humans and to the environment. |

|

CO2 -Footprint

ecodye: 2 for 1 principle

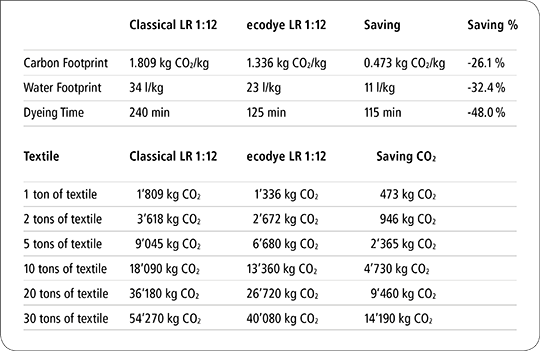

Dyeing 2 tons of textiles with ecodye saves 1 ton of CO2 emissions.

Reduce your carbon footprint by using ecodye auxiliary concept. A conventional dyeing process of 2 tons of textiles causes approximately 3.6 tons of CO2 emissions. The use of ecodye reduces your CO2 emissions dramatically up to 26 % (almost 1 ton). This auxiliary concept accelerates the dyeing process of polyester yarns and piece goods, thereby saving CO2 emissions, water and time.

|

ecodye trials – CO2 footprint calculation

Calculation base:

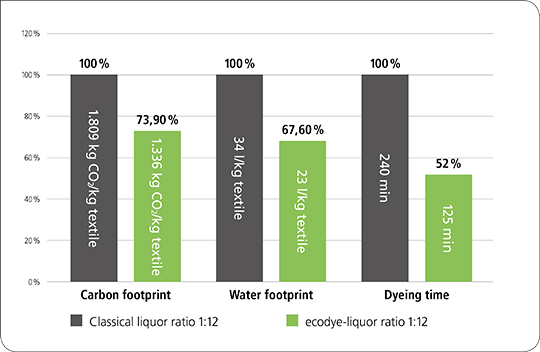

Considering a ratio of 1:12 the CO2 footprint calculation shows a significant reduction of CO2 emissions of 26.1% when using ecodye. This result corresponds to savings of almost 0.5 ton CO2 emissions per ton of textiles. |

Carbon footprint comparison

Furthermore, with the help of ecodye, water consumption can be dramatically decreased from 34 to only 23 litres per kilogram textile while dying time is accelerated by almost 50%. |